Tree Top’s Product Development Team is often asked about juice filtration. I thought it might be valuable to some of our customers to understand the types and term used for filtration.

When you demand purity, filtration is a great technology that helps to get the job done. From maintaining incoming water quality specifications to separating materials into refined component streams, filtration is relied upon for providing high yield purification without damaging delicate beneficial compounds.

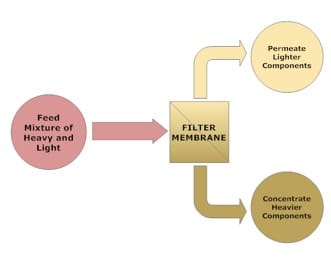

Liquid filtration relies on the principle of size separation. In the same way that a pasta strainer works to separate noodles from cooking liquid, filter membranes are designed to hold back components above a certain size. Pores in the filter media allow smaller particles to pass through to the permeate stream, while retaining larger particles in the concentrate stream.

Determining what you want filtered out and what you want to remain will help guide the correct filter pore size selection. Filter membranes are relegated to one of several classes based on the size of particle you are attempting to separate. Depending on the desired outcome, one or more of these types of filters can be used.

When we simply press fruit, the initial juice has many small particles suspended within it making the juice naturally cloudy. Our delicious 100% Pure Pressed Sweet and Tart Apple Cider is a good example of what this looks like. In our cloudy juices some of the particles within the juice can settle during shipping and distribution leaving a slight layer of solids on the bottom of the bottle. These are easily redistributed by gently inverting the bottle several times. In order to make a clear product like our 100% Pure Pressed 3 Apple Blend of juice, we use tightly controlled filtration membranes to provide us with excellent separation of the fruit cell solids. The resulting crystal clear juice maintains the natural color and flavor compounds found within the juice without damaging heat sensitive phenolics, phytochemicals and antioxidants.

Tree Top is always looking for new ways to leverage filtration to provide outstanding products that have added benefits over standard processing methods. In addition to the applications of industrial water treatment, we have been reviewing the ability of additional filtration membranes to concentrate juice without using heat and vacuum systems. Another potential research area is the use of certain filters to concentrate natural color compounds. These technologies could provide added benefits of targeted purified streams of juice components with greater yield and more accurate separation of the desired compounds.

Explore all our fruit juice concentrate offerings here. If you are looking for assistance in developing a custom formulation, Tree Top’s R&D team can help you with your next product innovation. Our research and development department is ready to help find the right fruit solution for you.

Contact our fruit ingredient experts at (800) 367-6571 ext. 1435.