Tree Top’s Food Safety Journey – Part II

Bad bugs, bad bugs, whatcha gonna do?

It really doesn’t take much of the wrong organism – Listeria, E. coli, Clostridium – to make a person ill. So, when we start to design our food preservation systems, one of the first questions we need to answer is: How many organisms do we need to kill?

Knowing your ingredient materials plays a big part in helping to answer that question. Here are some things to consider:

- Are you working with an ingredient sourced directly from a farm or field?

- Was it grown in the ground, above the ground, or in a shell or casing?

- How was it stored and for how long?

- Were any fermentation processes involved in creating the ingredient?

- What is the climate of the region where your ingredients were grown?

These factors along with others will determine what kind of starting micro load you can expect and what type of organisms you might encounter that could spoil a product or harm consumers. The most accurate way to understand your starting micro load will be to ask your supplier and perform tests.

They’re multiplying!

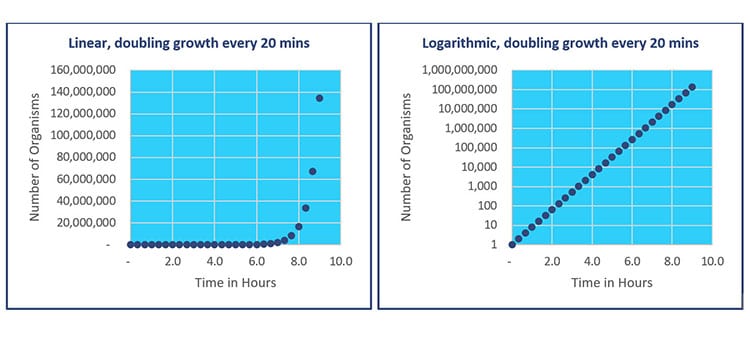

When we look back at infectious doses of organisms from the previous article, we see that on the high end we might need as many as 1,000,000 Salmonella or as few as 100 E. coli or Listeria to have a negative effect on a person’s health. We know under perfect conditions some pathogens have the ability to double every 20 minutes. The logarithmic scale pictured provides us a great view of how consistently the populations follow this established exponential growth model.

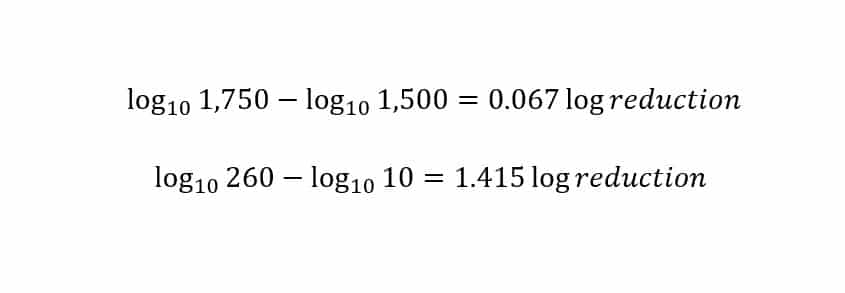

A log kill is defined as a reduction in the number of microorganisms by one order of magnitude. This adjustment of the scale from linear to logarithmic has some interesting implications. To quickly understand differences in orders of magnitude, we just move the decimal one place to the left. If we are reducing by one log, 100,000 organisms become 10,000 organisms after one log reduction. But this also changes how we think of differences between numbers of organisms. Even though the difference between 1,750 and 1,500 organisms is the same as between 260 and 10 organisms, the starting values in each scenario play a huge role in interpretation.

When we apply a thermal treatment to reduce the number of organisms, the same “order of magnitude” way of looking at the organisms is utilized. If an incoming material starts into the thermal process with 1,000,000 colony forming units per gram (cfu/g) we would calculate reductions in the following manner:

1-log kill à 100,000 cfu/g remaining; potentially sufficient kill if the infectious organism is Salmonella

2-log kill à 10,000 cfu/g remaining; potentially sufficient for Salmonella

3-log kill à 1,000 cfu/g remaining; potentially sufficient for Salmonella

4-log kill à 100 cfu/g remaining; potentially sufficient for Salmonella

5-log kill à 10 cfu/g remaining; potentially sufficient kill if the organism is E.coli, Salmonella or Listeria

Taking ‘em down

When we discuss how much treatment is needed knowing the incoming load and target organism, we also need to define where we want to end up. There are two different terms used when relating to a standard of microbial reduction. The first term that I’ll explore is pasteurization. This term was defined by the National Advisory Committee on Microbiological Criteria for Foods in 2006 as:

Any process or treatment or combination thereof that is applied to food to reduce the most resistant microorganism(s) of public health significance to a level that is not likely to present a public health risk under normal conditions of distribution and storage.

Pasteurization is typically thought of as a 5- or 6-log kill of some defined organism that can cause health issues in humans. The reason that these are generally recognized as targets for pasteurization is that they are defined in what are termed Safe Harbors. Juice HACCP (5-log kill of Cryptosporidium parvum, a protozoan found mainly in water) and the Pasteurized Milk Ordinance (6-log kill of Coxiella burnetii, the causative agent of Q-fever) are both longstanding and widely-accepted documents relating thermal conditions that achieve low risk of harm to public health.

Why did they start or end with 5- or 6-log of organisms? There really isn’t any sound justification that I have seen explaining the starting load, just a general expectation that evaluations of ingredients tainted to this level with microorganisms would be readily apparent and result in rejection of the incoming material. This, however, may not be entirely accurate for all food types.

A heated discussion

The second term we use to relate microbial conditions of finished product is commercially sterile or aseptic. This has been defined by the Food and Drug Administration (FDA) for us in 21CFR Part 113, subpart A, Section 113.3 – Definitions

(e) Commercial sterility:

(1) “Commercial sterility” of thermally processed food means the condition achieved –

(i) By the application of heat which renders the food free of –

(a ) Microorganisms capable of reproducing in the food under normal nonrefrigerated conditions of storage and distribution; and

(b ) Viable microorganisms (including spores) of public health significance; or

(ii) By the control of water activity and the application of heat, which renders the food free of microorganisms capable of reproducing in the food under normal nonrefrigerated conditions of storage and distribution.

By this definition, there should be no viable organism or spore left in the food product. For low-acid canned foods a 12-log reduction of spores of Clostridium botulinum is used as the target.

The amount of thermal treatment that goes into any specific product to achieve either of these conditions depends largely on the attributes of the product itself. When finetuning the needed thermal treatment, there are other considerations that might reduce or increase the cook temperature or time:

- Does it have a lowered pH, which will reduce the ability of remaining spores to grow in the food product?

- Are there any additives that reduce the ability for microbes to survive and thrive like salt or sorbates?

- Is the storage environment, temperature or atmosphere altered to reduce the ability of organisms to survive?

- What is the available moisture? Can scarcity of water serve to remove any possibility of organisms reproducing in the stated storage conditions?

- Are there any hardy spoilage organisms (yeast, mold, etc.) that can affect the above-mentioned conditions if present in a sealed container?

Up next

That’s a wrap for this blog. In the next installment of this ongoing series chronicling Tree Top’s food safety journey, I’ll dive into:

- Validation questions and setup

- Surrogates

- Running tests

- Interpreting data

- Continuous control and monitoring

Until then, please contact us, if you want to know more about our food safety policies and processes.

In case you missed the first part of this blog series Tree Top’s Food Safety Journey – Part I