In any food manufacturing process there are inherent risks that need to be assessed and mitigated. There are obvious risks, such as microbial, or foreign matter contamination, but also risks that are not as easily assessed, such as human errors. Process mapping is an effective tool to determine the risks throughout the manufacturing operation. An effective risk assessment begins with identifying possible hazards prior to harm being inflicted due to the hazard. Identification allows for preemptive controls to be put in place to mitigate the hazard. Food manufacturing facilities must be ever vigilant to evaluate and mitigate risks to the processes and products in the operation.

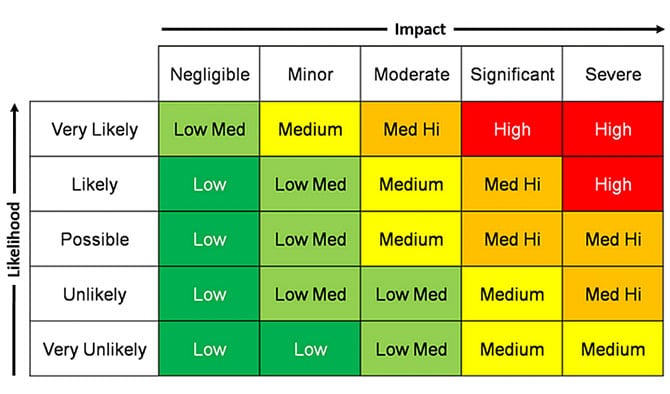

Asking the question, “What is the risky process we have right now?” is essential to staying on top of risks. Once risks are identified, the next step is to identify who the hazard could affect. A hazard or risk can cause harm to the business, employees, consumers, etc. depending on the identified risk. After the risk and the impacts on who could be harmed are identified, the next step is to systematically evaluate the risk or hazard. Many organizations use a matrix like the one below to determine a visual evaluation of risks.

Source: https://www.armsreliability.com/page/resources/blog/beyond-the-risk-matrix

As the likelihood of the of the risk occurring increases and the severity of the risk impact increase, the risk is deemed higher risk. Low risk hazards may require minimal mitigation while high risk hazards require immediate and extreme mitigation. In the evaluation process, it is important to document the assessment and evaluation process.

After the hazard has been identified, the impacts have been assessed, and all has been documented, the next step is to mitigate the risks. Mitigation, depending of the risk matrix will guide the severity of the actions to be taken. It may not be possible to reduce the risk completely but lowing the risk level is the goal.

Risk assessment is a common tool in the realm of food safety, as well as in the areas of employee safety. Ensuring the safety and well-being of our customers and employees is key to producing safe and quality foods. Tree Top, Inc. employs risk assessment techniques to not only identify risks to food and employee safety, but also risks to the quality of our products. This ensures our products continue to be of the highest quality. Risk assessment is ultimately a tool for continuous improvement. As hazards and risks decrease, the evaluation of quality and system improvements increase. This is the ultimate goal of an effective Risk Assessment program.

I’m always happy to answer questions about our risk assessment techniques. Feel free to contact me at Kristine.mcdonald@treetop.com